Surface analysis

CSI Nordic is able to solve surface related problems with advanced surface techniques. A problem can for example be discoloration on metal surfaces, trouble with surface finish or maybe adhesion problems of thin coatings. We can determine chemical composition and thickness of nanometer thick films or micrometer thick metal coatings

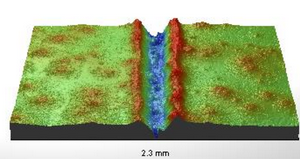

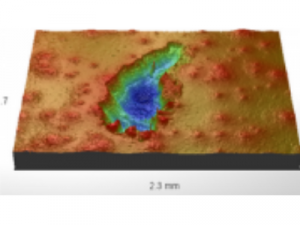

Surface topgraphy and coordinate measurement

CSI Nordic performs topographical measurements on products to determine surface roughness and geometry. We perform measurements on a macroscopic level with a coordinate measuring machine and determine surface roughness to control if a component fulfills its tolerances. Topographic measurement is often used during failure investigations to quantify the extent of surfaces damages such as corrosion depth or removed material volume on a worn tool surface.

Contact us to see how we can help you with your surface related questions or if you need help analyzing surface topography or possible surface contamination.

Equipment

- FT-IR spectrometer, Spectrum One Perkin Elmer. Organic material such as plastics, oils, fats etc.

- Elecron diffraction X-Ray analysis (EDX), Oxford PentaFETx3. All electric conductive materials

- Electron backscatter diffraction (EBSD), Oxford Instruments HKL, NordlysF. Is used to determine phases and grain orientation

- Auger electron spectroscopi (AES), PHI 700 Field Emission Scanning Auger Nanoprobe. Chemical analysis on nanometer level. Only electric conductive material

- Scanning electron microscopy (SEM), Zeiss ULTRA 55. All materials

- Time of fligth secondary ion mass spectrometry (ToF-SIMS), PHI TRIFT II, Chemical analysis on nanometer level. All materials

- Interference profilometry, Wyko NT9100. 3D-topographical mapping on nanometer level.

- Coordinate measuring machine, Johansson Coordimatic CEJ 7000. Measures geometry of components with micrometer precision.